Modix3D

Modix BIG180X V4 3D Printer Kit

The Modix BIG-180X V4 is a large-scale 3D printer designed for professionals and innovators. It has a massive print volume of 1800×600×600mm and comes as a self-assembly kit. Known for its high-quality components, durability, and great price-performance ratio, it also offers upgrade options for customization. The printer uses top components from brands like E3D, Duet, and Hiwin, ensuring reliability and capacity for future upgrades.

- Massive print volume of 1800×600×600mm

- High-quality components

- Heavy-duty design for robust output

- Assembly & Installation Services Available

Remove from wishlist

Add to wishlist

loading...

Product No.

loading...

Financing Available

Notify me when this item becomes available

Success

You will be notified when ... becomes available.

Request A Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

Success

Thank you for your request. We will be in touch shortly.

Modix BIG-180X V4

SCALE UP YOUR PRINTER AND PRODUCTION

Transform your manufacturing workflow with the Modix BIG-180X 3D Printer. With a massive print volume of 1800×600×600mm, premium components, and modular construction, this powerhouse digital manufacturing machine is ideal for professionals and passionate innovators who produce for large-than-life projects.

Key Features of the Modix BIG-180X V4 3D Printer Kit:

- Large Print Volume: 1800×600×600mm

- Assembly: Self-Assembly Kit

- Need installation assistance or training? Request a quote for more info.

- High-quality components used for reliability

- Heavy-duty design to withstand robust output

- Upgrades/Add-ons available for full customizable control

- Fantastic price-to-performance ratio

PRINT BIGGER WITH MODIX 3D PRINTER KITS

For experienced FDM printing users, Modix offers large 3D printers with some of the market's largest print volumes. Produce huge models in one complete piece for stronger finished parts and shorter post-processing time.

Incorporating top-quality components from reliable renowned brands like E3D, Duet, and Hiwin, Modix printers are designed for heavy-duty use and modularity, anticipating potential future upgrades to keep up with the continuously evolving 3D printing market.

KNOW YOUR PRINTER FROM THE INSIDE OUT

Modix 3D Printers are sold as self-assembly kits, offering many advantages such as hands-on knowledge of your printer, high-cost savings, and flexibility in machine placement within your production facility. Assembling the printer enhances your ability and confidence to upgrade, maintain, and customize it, ensuring its longevity in your workflow.

Each Modix kit includes physical and online assembly instructions full of detailed step-by-step guides, video demonstrations, and 3D models of sub-assemblies, making the assembly process straightforward and intuitive.

UNPRECEDENTED LEVELS OF MODULARITY AND CHOICE

Modix's design philosophy centers on modularity, providing customers with the freedom to choose filament, slicing software, and printer upgrades. New upgrades and components, like air filters and print head configurations, are regularly evaluated for compatibility.

Depending on the model, upgrades may already be included or can be easily added at purchase, allowing customization to personal budgets and needs. Modix also publishes optional customization guides through their online service portal, supporting any desired upgrades.

EXPEDITED AIR-FREIGHT SHIPPING—AVAILABLE NOW!

Need your printer faster? MatterHackers offers an Expedited Shipping option which ships the kit directly from Modix's overseas warehouse via Air Freight instead of Ocean Freight.

The shipment clears US Customs, arrives at Modix's US-Based warehouse, and then ships directly to the end customer. Customers are not expected to receive any additional Customs, Duties, or Taxes on the Import.

Note: Expedited shipping is an additional charge on top of standard freight shipping fees.

Request this option at time of purchase. We cannot change shipping methods from Ocean Freight once an order has been accepted.

Contact support@matterhackers.com or click "Request a Quote" to inquire about this option.

What Upgrades Are Available with the Modix BIG-180X 3D Printer Kit?

| UPGRADE |

DESCRIPTION |

| IDEX |

+$900 |

|

IDEX = Independent Dual Extruder

Easily print advanced models with internal geometries by having one

printhead extrude the core thermoplastic material and use the other

to extrude water-soluble support filament

Includes:

- Secondary printing subsystem: Griffin print head, clog detector,

PTFE, spool mount.

- Motion system: secondary Y axis motor with the required

components (belts, pulleys etc.).

- Metal brackets for both Y axis and print heads

- Wires, drag chains and optical end-stops.

|

| Tilt Screen |

+$200 |

|

This upgrade is a combination of the following:

- Screen is mounted on an articulated arm for easier access

(adjust height, rotate screen, etc).

- Frontal power switch installation (convenient access)

- Large (secondary) emergency button (improved accessibility)

The "Standard" option means that the screen will be attached directly

to the printer (no flexible mobility), no frontal power switch, and only

one emergency button. |

| Magnetic Bed |

+$1530 |

|

Magnetic beds make part removal easier.

One side is coated with PEI, providing a textured bottom surface, and

the other side is applied with a PEI sheet for a smooth, glossy bottom

surface.

Each bed is 660*660mm in size so a total of 3 pieces are provided to

cover the entire printer's build surface.

|

| Active Air Filter |

+$900 |

|

An external three-phase filter device that repeatedly cleanses the air

during the printing process through a pre-filter (for dust), then HEPA

(for sub-micron particles), and finally through the active carbon filter

(for fumes).

This is a MUST-HAVE upgrade if you intend to print with any plastic

beyond PLA (PETG, ABS, etc.). |

| Extended Warranty |

+$1000 |

|

Extend your standard warranty coverage from one year to two.

Reminder: Warranties do not cover degradable (PEI sheet and

nozzles) and consumables. |

Want to learn more about these upgrades? See our Features section.

Modix Printer Model Comparison

What Features are Available on Generation 4 Modix 3D Printers?

Modix Generation 4 introduces advanced capabilities such as internal geometry printing, faster print speeds, reduced post-processing time, and enhanced reliability. Like previous versions, this new generation was designed with backward compatibility in mind so owners of Modix’s printers enjoy upgrades from time to time in both configurations and hardware. These updates expand the possibilities of the Modix ecosystem, ensuring a cutting-edge experience for users.

All Modix 3D printers in the Generation 4 line share the same core design based on Modix BIG-60 V4.

Some models have varying upgrades that are included instead of optional.

See below what you can expect:

Chassis & Enclosure

Crafted from solid 40x40 T-slot aluminum profiles, the chassis features powder-coated laser-cut aluminum brackets and joints. The 3mm black Aluminum Composite Panel (ACP) enclosure, available for purchase or included on select models, enhances stability and environmental control.

- Solid 40X40 T-slot aluminum profiles

- Powder coated laser cut aluminum brackets and joints

- Enclosure – Closed enclosure made of 3mm black Aluminum Composite Panels (ACP)

Electronic Controller

Modix printers are powered by the Duet 2 WiFi 3D printer controller, a reliable and widely supported platform for professional 3D printers. Enjoy a seamless printing experience with the following benefits:

- Powerful 32 Bit Processor

- Dedicated WiFi module with external antenna

- Quiet TMC2660 stepper drivers (up to 256 micro-stepping)

- High-speed uSD card + support for a second external SD card (if required)

- Dual extruders are controlled on the main board, up to 5 additional stepper motor drivers are controlled on the DUEX expansion board.

- High Power rating: Each stepper driver is capable of 2.8A motor current, currently limited in software to 2.4A.

- Access the printer via a PC, tablet or smartphone on a local network.

- Set up and control your printer through the web interface.

FULLY AUTOMATED CALIBRATION

All Modix printer kits are delivered with the electronic expansion board named “Duex 5”. A dedicated stepper motor driver is allocated for each Z and X axis motor. As a result, Modix is now offering a full set of automated calibration routines including:

- Bed tilting calibration

- Bed leveling

- Gantry alignment

- Z offset calibration

INTERFACES

- Touch Screen- 7-inch Duet3D touchscreen integrated with the controller

- An emergency stop button is equipped next to the screen on all Generation 4 printers. The stop button resets the Duet controller and stops printing immediately.

- An optional large secondary emergency button can be installed with the Tilt upgrade.

- Web Interface – WiFi web access for remote control from either mobile or PC. Upload print files directly from your workstation

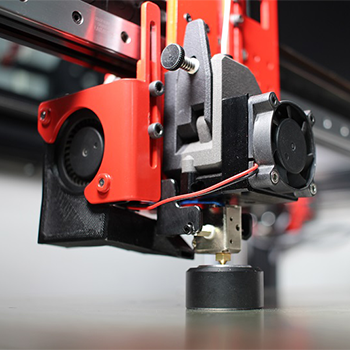

GRIFFIN PRINT HEAD ADVANCEMENTS

Included on all Modix 3D printers is the Griffin Print Head, a collaborative creation comprising a custom Bondtech extruder (based on the BMG model) and a new hotend designed by Modix. Improvements include:

-

High Flow Rate & High Printing Temperatures: The Bondtech extruder features a double drive-gear system and a nickel-coated copper heat-block for enhanced heat transfer and high-temperature compatibility. It incorporates a Slice Engineering Bi-Metal heat-break and an upgraded PT-1000 temperature sensor, supporting printing up to 500°C.

-

Increased Reliability: The new design minimizes risk of print-head damage via a three-faced, rigid heat-block mount for higher impact resistence. It also accommodates the longer E3D Super Volcano with a dedicated adapter, enhancing reliability and versatility.

-

Streamlined User Experience: The redesigned print-head architecture simplifies nozzle replacements, facilitated by the secure, single-handed heat-block detachment. This seamless process ensures effortless transition between various nozzle diameters, amplifying user convenience.

-

Effortless Switch: The novel mounting bracket design and the D shaft configuration of the Slice Engineering heat-break synergize to enable swift and hassle-free substitution of the entire filament melting subsystem. This innovation empowers users to swiftly transition between dedicated setups tailored for specific filament types—be it abrasive carbon-infused filament or PLA prototypes.

-

Condensed Design: The enhanced print-head design retains the compactness of its predecessor while preserving generous Z-axis travel capabilities. This thoughtful evolution harmonizes seamlessly with the extensive range of E3D Volcano nozzles, encompassing an array of sizes and materials.

-

Smart Calibration: The upgraded print-head enables automatic Z offset calibration between the nozzle and the BL Touch probe, streamlining the calibration process. A dedicated sensor ensures accurate calibration and stores the relative distance between the probe and the nozzle.

Note that for temperatures surpassing 300°C, it is essential to replace the brass nozzle with a higher-temperature compatible alternative.

IDEX DUAL PRINTING (Optional)

With Independent Dual Extruder (IDEX) technology, the Modix printer can print models with internal geometries and dense support layers. This add-on improves print quality, reduces post-processing effort, and enhances success rates for complex prints.

IDEX is an optional upgrade for all Generation 4 printers and includes the following:

- Secondary Printing Subsystem: Includes the Griffin print head, clog detector, PTFE, and spool mount.

- Motion System: Incorporates a secondary Y-axis motor along with necessary components such as belts and pulleys.

- Metal Brackets: Equips both the Y-axis and print heads with sturdy metal brackets.

- Wires, Drag Chains, and Optical End-stops: All essential wiring, drag chains, and optical end-stops are thoughtfully included.

AUTOMATIC FILAMENT CHANGER

Modix's IDEX also serves as an automatic filament changer, capable of switching between print heads automatically upon detecting filament run-out when using the same filament type. Benefits of this innovation include:

- Enhanced Efficiency: This IDEX Filament Changer eliminates downtime, allows continuous operation, and saves valuable time by autonomously switching between spools and minimizing the need to constantly monitor and maintain the printer.

- Elevated Print Precision: Not only does this save time but it also enhances print quality. Avoiding frequent enclosure openings to do filament changes maintains chamber temperature. This prevents model shrinkage resulting in fewer defects.

SUPER HIGH FLOW HOTEND

The optional Super Volcano hotend high flow add-on is based on the E3D super volcano heat-block and nozzle and ideal for fast printing of large, bulky objects and stronger, single-walled vase mode style objects. It's delivered with a stabilizing CNC-made mounting bracket, reducing vibrations for high print quality.

Add-On Includes:

- E3D SuperVolcano Heater Block

- 1mm Brass Nozzle

- Slice Engineering Bi-Metal Heat-Break

- 80W Heater

- CNC Adapter

- Blower Fan & Duct

Tilt Screen & Emergency Button & Frontal Power Switch

The Tilt Screen is mounted on an articulated arm for user-friendly convenience. Effortlessly adjust the screen left, right, upward, or downward to ensure optimal visibility and ease of use.

The (secondary) Emergency Reset Button resides on the machine's front panel for swift access. Ensure immediate interruption of print jobs whenever necessary for even more control and safety.

The Frontal Power Switch is an easily accessible power on/off button positioned at the front. This is useful when the printer is situated in confined spaces.

MOTION SYSTEM

Benefit from precision motion with HIWIN linear guide rails, Z ball screws, reinforced belts, and NEMA motors. Achieve travel speeds up to 350 mm/sec for fast and efficient production.

- HIWIN MGW9H linear guide rails

- Four Z ball screws for Z axis movement. 12mm diameter, 4mm pitch

- 9 mm width Gates GT2 timing belt, reinforced with fiberglass

- Motors: X & Z Axis: NEMA-23, Y Axis: NEMA-17

- Mechanical position accuracy: X-10 Micron, Y-10 Micron, Z-0.5 Micron

- Print speed (based on 0.4mm nozzle):

- Up to 100 mm/sec – normal quality

- Up to 250 mm/sec – draft / non functional infill

- Up to 350 mm/sec – travel

- Larger nozzles normally are required to print slower but provide parts much faster due to a reduced number of layers.

POWER

- Support both 110V and 230V

- For electronics: Meanwell 24V 280W Power Supply

- Protections: Short / Over-load / Over-voltage / Over-heating.

- No load power consumption<0.5W

- LED indicator for power on

- Aviation grade switches and connectors

- Heat Bed AC powered heater 1370 Watt

- PID bed heater controller by Autonic

- BIG METER and 180x require 208-240V, 32A connections

- North America customers: NEMA L6 30P 30A outlet

- EU/AU/UK customers: IEC 309 32A Blue (2P+E) outlet

- Tripp Lite PDU for meter and 180x

- North American customers: https://www.tripplite.com/support/PDUH30HV

- EU/AU/UK customers: https://www.tripplite.com/support/PDUH32HV

PRINT BED AND REMOVABLE MAGNETIC BED

Modix 3D printers use a 6.35mm Alcoa Mic6 milled cast aluminum plate made in the U.S. Its 1370W (1200W for 110V users) AC powered bed heater requires a dedicated independent 15A AC source. If you need to print small objects 200×200mm or less in size, utilize the dual heating zones for lower power consumption. All printers achieve a max bed temperature of 110°C (w/ enclosure) and come stock with a PEI film print surface you can apply directly to the bed.

Alternatively, you can purchase the Magnetic Bed upgrade. This optional feature improves user experience and saves time by allowing immediate removal of printed objects instead of waiting for the cool down. It includes an adhesive magnetic sheet that attaches to the aluminum bed plate, a removable dual-sided spring steel plate for textured or glossy bottom layer finishes, and simplifies maintenance by facilitating easy PEI replacement.

Software

Utilize the open-source Duet RepRap firmware and choose from popular slicers for customization. Users can choose from any available slicer and 3D printer controller.

Modix printers are compatible with:

Specific printer configurations are supplied in the customer zone.

CLOG DETECTOR

All Modix 3D printer now comes with a Clog Detector which comes with a custom highly sensitive encoder capable of detecting for following potential failures:

- Hot-end clogs

- Knots in the filament spools

- Filament run-out

- Under extrusion (i.e. when nozzle temperature is too low, nozzle is too close to the bed, etc.)

When a failure is detected, the printer pauses, and the print job can be saved.

ACTIVE AIR FILTER (RECOMMENDED)

The Modix Active Air Filter (MAAF) is an external device designed to purify the printer's chamber from fumes and particles during 3D printing without affecting print quality. Use the Frontal Speed Selector to keep airflow speed low during printing and bump it up at the end for thorough cleansing afterward. Using a multi-layer filtering system, it maintains a continuous air cleansing process.

Sub-micron particles and fumes from melted plastic can pose health risks so this upgrade is highly recommended when printing with materials beyond PLA or in rooms without proper ventilation.

- Removes micro-particles and fumes

- Utilizes three-filter system

- Pre-Filter (for large particles)

- HEPA Filter (for tiny particles)

- Active Carbon Filter (for fumes)

- Reduces health risks, especially when printing beyond PLA (PETG, ABS, Nylon, etc.)

- Airflow control maintains temperature during printing and thorough cleansing afterward

- Spare filters required every 3 to 12 months, indicated by a front panel alert.

CRASH DETECTOR

Every Modix 3D printer now includes this additional layer of safety in rare cases where the BL-Touch bed leveling probe fails and this failure is not detected by the printer controller.

The detector will prevent the print head from crashing into the bed plate.

POWER DISTRIBUTION UNIT (PDU)

The PDU is a very convenient cable management solution. Connect one cable instead of three AC cables to the wall for peace-of-mind organization.

WIDE FILAMENT COMPATIBILITY

Modix 3D printers' print heads support almost any existing filament including:

- Standard Materials: PLA, ABS, PETG, Nylon, flexibles (TPE & TPU), PHA, Co-Polyester

- Composites (Carbon fiber, Glass fiber, Wood, Copper, Brass, Magnetic, etc.)

- Make sure to use abrasive-resistant nozzles when printing composites (separate purchase, see Tech Specs)

- Support (PVA, Hips)

Any filament from any vendor can be used.

8KG SPOOL SHELF

The spool mounting shelf gets a refreshed design inGeneration 4, which now enables mounting 8kg 3D printer filament spools.

Technical Specifications

| PRINTER PROPERTIES |

|

| Machine |

3D Printer |

| Technology |

Fused Deposition Modeling (FDM) /

Fused Filament Fabrication (FFF) |

Print Volume

(W × D × H) |

1800×600×600mm

(~70×23.6×23.6 inch) |

Machine Dimensions

(W × D × H) |

2170×1060×1430mm

(~85.4×41.7×56.3 inch) |

| Shipping Weight |

200kg (440.9 lb) |

| Assembly |

Self-Assembly Kit |

| Closed Print Chamber |

Included |

| Enclosure Type |

Aluminum composite panels (ACP), 3mm thick.

Polycarbonate doors and top lid |

| Feet |

Articulated leveling feet included, Casters included |

| PRINT HEAD |

|

| Number of Print Heads |

1 × Griffin Print Head

- Optional Upgrade: IDEX |

| Default Filament Diameter |

1.75mm

- Can be converted to 3mm by the user |

| Extruder Brand & Model |

Modix Griffin Printhead (Based on Bondtech BMG) |

| Hotend Brand & Model |

Modix Griffin Printhead |

| Included Nozzles |

Volcano Brass 0.4mm, 0.6mm, 0.8mm Primary hotend

OPTIONAL SEPARATE PURCHASE

- If printing composite filaments, abrasive-

resistant nozzles are required for printing

composite filaments.

- Nozzle X Volcano Nozzles (for Griffin)

- Nozzle X v6 Nozzles (for Griffin High-

Resolution Printhead)

- If printing beyond 300°C, use the appropriately

rated nozzle for your application.

- Nozzles that come stock on the Griffin and

High-Resolution Printheads are Volcano

Brass, rated up to 300°C

- For nozzles rated up to 500°C, check

out Plated Copper Nozzles

- Choose "Volcano" sizes for the

Super Volcano and Griffin

- Choose "v6" sizes for the Griffin High

Resolution printhead

- Choose "SuperVolcano" sizes for the

SuperVolcano printhead

- Nozzle X is rated up to 450°C

|

| Hotend Max. Temperature |

500°C

- if using the default Griffin Printhead or optional

E3D SuperVolcano Printhead

285°C

- if using the optional Griffin High-Resolution

Printhead

|

| Extruder Motors |

Motech MT-1703HS168A

Direct drive extruders gear reduction of 1:3 |

| Filament Runout Sensor |

Dedicated sensor per extruder |

| MOTION |

|

| X & Y Axis Linear Guides |

HIWIN MGW9 |

| Z Axis Guides |

HIWIN MGW9 |

| X & Y Axis Drive System |

Gates GT2 width: 9mm, fiberglass reinforced |

| Z Axis Drive System |

SFU1204 Ball screw 2:5 belt gear reduction |

| X-Axis Motors |

2 × Motech MT-1705HS200A |

| Y-Axis Motors |

1 × Motech MT-1705HS200A |

| Z-Axis Motors |

4 × Motech MT-1705HS200A |

| Resolution (XYZ) |

4 × 4 × 0.5 micron |

Speed

(based on 0.4mm nozzle) |

Up to 100 mm/s – normal quality

Up to 250 mm/s – draft / non-functional infill

Up to 350 mm/s – travel |

| Printing Acceleration |

Up to 1000 mm/s2 |

| PRINT BED |

|

| Bed Plate |

Alcoa Mic-6, 6.35mm milled cast aluminum plate |

| Number of Heaters |

3 × AC heater, 1,350 Watt, Triple zone |

| Temperature Controller |

Autonics TCN4 PID controller |

| Max. Bed Temperature |

110°C (w/ Enclosure) |

| Bed Leveling Probe |

BL Touch Probe |

| Bed Leveling |

Bed shape is measured by probing 100 different points. |

| Bed Tilt Leveling |

Semi-Automatic, guided by an on-screen macro |

| Bed Motion System |

4 × ball-nut screws

Each screw is mounted to a dedicated stepper motor

with a belt gear system |

| ELECTRONICS |

|

| Electronic Controller |

Duet3D: Duet2 Wifi & Duex5 Expansion board |

| User Interface |

7” Touch screen – PanelDue from Duet3D |

| Remote Control (WiFi) |

Upload Gcode files right from your desktop |

| Direct Connectivity |

SD Card, USB cable |

| Ethernet |

Optional with Duet3D Ethernet board.

Should be purchased and replaced by customer |

| Electronics (DC) Power |

Meanwell 24V/280Watt power supply powering the

electronic and motion system.

Universal AC input: 110-230V, 50/60 Hz |

| Bed Heaters (AC) Power |

Minimal Electricity requirements:

32A, single phase, 208-240V:

- N. America customers: NEMA L6-30P outlet

- EU/AU/UK: IEC 309 32A Blue (2P+E) outlet

|

FAQ

I would like help assembling and installing my Modix - can MatterHackers help?

Yes! We offer assembly, installation, and maintenance services for all Modix printers. You can learn more about that here.

How long will it take to my purchase from MatterHackers to be shipped?

Items purchased from MatterHackers will be shipped from the manufacturer's US-based warehouse. There may be a lead time on orders, depending on stock availability

Can I return a 3D printer kit if it has been opened?

Returns will not be accepted for any opened 3D printer kit. New, unopened 3D printer kits may be returned within 30 days of purchase.

What kind of support does MatterHackers provide for warranty replacement components?

MatterHackers provides support for warranty replacement components. Assembly instruction, troubleshooting, and technical support are provided directly by the Modix Support team.

support@matterhackers.com or click \"Request a Quote\" to inquire about this option.</p>\r\n</div>\r\n</div>", "Images": [], "Type": "Text", "ElementCode": "I6TATQ"}, {"Content": "<h3><strong><a id=\"upgrades\"></a>What Upgrades Are Available with the Modix BIG-180X 3D Printer Kit?</strong></h3>\r\n<div class=\"table-responsive\">\r\n<table class=\"table\">\r\n<tr>\r\n<td class=\"align-center\"><strong>UPGRADE</strong></td>\r\n<td><strong>DESCRIPTION</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><strong>IDEX</strong></td>\r\n<td><strong>+$900</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><img alt=\"Independent Dual Extrusion add on for the Modix BIG-180X 3D printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/-JagPINsZxE8AQnrtH2biYo4Ps8W-PBTlsrKKR3KZq1MO8SGHmGJHR3z-hkGCb1bt1kBN6OjRCpdA0uglrbhPfT8qrEa8QykuAk=s150/" /></td>\r\n<td>IDEX = <strong>I</strong>ndependent <strong>D</strong>ual <strong>Ex</strong>truder<br /><br />Easily print advanced models with internal geometries by having one<br />printhead extrude the core thermoplastic material and use the other<br />to extrude water-soluble support filament<br /> <br />Includes:<br />\r\n<ul>\r\n<li>Secondary printing subsystem: Griffin print head, clog detector,<br />PTFE, spool mount.</li>\r\n<li>Motion system: secondary Y axis motor with the required<br />components (belts, pulleys etc.).</li>\r\n<li>Metal brackets for both Y axis and print heads</li>\r\n<li>Wires, drag chains and optical end-stops.</li>\r\n</ul>\r\n</td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><strong>Tilt Screen</strong></td>\r\n<td><strong>+$200</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><img alt=\"Tilt Screen add on for the Modix BIG-180X 3D printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/PRkqEtZDRwQYwzN55j8NN0VpbJQ8SMFBWZ3kQW9CnhXyxWAnrcKbDSkiA1eFsAAC579LXW92q41DeVXfgnb5LfQPghXxbwpFLtoL=s150/" /></td>\r\n<td class=\"align-left\">This upgrade is a combination of the following:<br />\r\n<ul>\r\n<li>Screen is mounted on an articulated arm for easier access<br />(adjust height, rotate screen, etc).</li>\r\n<li>Frontal power switch installation (convenient access)</li>\r\n<li>Large (secondary) emergency button (improved accessibility)</li>\r\n</ul>\r\n<br />The \"Standard\" option means that the screen will be attached directly<br />to the printer (no flexible mobility), no frontal power switch, and only<br />one emergency button.</td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><strong>Magnetic Bed</strong></td>\r\n<td><strong>+$1530</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><img alt=\"Magnetic Bed add on for the Modix BIG-180X 3D printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/efV7KVJONDTM1ULrY2iwYvvii2XVmNergCNrAA8J6kdH_mlBuNFVuFEdzAc7sWQbA8tCh_FZWyTZ_EY13TlUdNV2MBNXwV5ndv4o=s150/" /></td>\r\n<td>\r\n<p>Magnetic beds make part removal easier.<br /><br />One side is coated with PEI, providing a textured bottom surface, and<br />the other side is applied with a PEI sheet for a smooth, glossy bottom<br />surface.<br /><br />Each bed is 660*660mm in size so a <strong>total of 3 pieces</strong> are provided to<br />cover the entire printer's build surface.</p>\r\n</td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><strong>Active Air Filter</strong></td>\r\n<td><strong>+$900</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><img alt=\"Air Filter add on for the Modix BIG-180X 3D printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/J0_l1np6-6niSsU_wBgPFgbdrcotBqekWWUhZKXqDWtlzbdLsfBWiHxU8r6tJc6C86ynxJAhLZzP4SdGOWvaYj7xgszqClbhQ7Dn=s150/" /></td>\r\n<td>An external three-phase filter device that repeatedly cleanses the air<br />during the printing process through a pre-filter (for dust), then HEPA<br />(for sub-micron particles), and finally through the active carbon filter<br />(for fumes).<br /><br />This is a <strong>MUST-HAVE</strong> upgrade if you intend to print with any plastic<br />beyond PLA (PETG, ABS, etc.).</td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><strong>Extended Warranty</strong></td>\r\n<td><strong>+$1000</strong></td>\r\n</tr>\r\n<tr>\r\n<td class=\"align-center\"><img alt=\"Extended Warranty add on for the Modix BIG-180X 3D printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/cvupakBUn4NemqJiw_4yH7bAg5P5rUrUXDmthjyvMmGbu9KiYX9o-mvW53b8hHIW1cKvbT1n5bf-3FrTz4DfUFjKXSKENNviBgg=s150/" /></td>\r\n<td>Extend your standard warranty coverage from one year to two.<br /><br />Reminder: Warranties do not cover degradable (PEI sheet and<br />nozzles) and consumables.</td>\r\n</tr>\r\n</table>\r\n</div>\r\n<p class=\"align-center\"><em>Want to learn more about these upgrades? See our <a href=https://www.matterhackers.com/"#features\">Features</a> section.</em></p>\r\n<hr />", "Images": [], "Type": "Text", "ElementCode": "R9RFPB"}, {"Content": "<h3><strong><a id=\"compare\"></a>Modix Printer Model Comparison</strong></h3>\r\n<div class=\"table-responsive\">\r\n<table class=\"table\">\r\n<tr>\r\n<th class=\"align-left\"></th>\r\n<th class=\"align-center\"><img alt=\"Modix BIG-60 3D Printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/27ZYN-ag9wPluHkC40idCOiSKZue3J-wSSBSTfRmyKAYvl1yvkaCE7gPKNDocYIsX7UY6cypMgsMIsxAZKXCNDEUXOuL5suQlVLK=s150/" /></th>\r\n<th class=\"align-center\"><img alt=\"Modix BIG-120X 3D Printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/lkZyQUHUX2JI0giDb0WetcYXtoGMC0Cbj4PVf8iCLpPPuOZnPx-5gZZhp9KBCjM3gB2Xcx40b8VeiVIHidlE0LROVm-v3PI0Xvp8Bg=s150/" /></th>\r\n<th class=\"align-center\"><img alt=\"Modix BIG-120Z 3D Printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/mPLy1MpFN-LHQ2bgLMGa0rATB6MDoIHdwU0WUaaW08SuS9aIJZJqmDt9INWKPxsNb6YxJmCsd8QEwR3StYmnT7jloCfmcfPcHZhf=s150/" /></th>\r\n<th class=\"align-center\"><img alt=\"Modix BIG-METER 3D Printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/AkskHpI1xIONhP-968z2ghNepsErehxVhSOtdmbiIJ-UNEkbrL2_jOLRETP5Yqy-LBPjoHmLmOMCcFvIN6IJ-rzfBEqk_34nhl4y=s150/" /></th>\r\n<th class=\"align-center\"><img alt=\"Modix BIG-180X 3D Printer\" src=https://www.matterhackers.com/"https://lh3.googleusercontent.com/MwNZOqTc-58_V4bOZm0y8kSOcs_lBwpfBzuhBoHZwO4AQ3wuhPNYu8EJezqL-ZO2VkYv5ZQNWQijArq54kjFXn6OcKZ9rCXfDGch=s150/" /></th>\r\n</tr>\r\n<tr>\r\n<th class=\"align-left\">Model</th>\r\n<th class=\"align-center\"><a title=\"Modix BIG-60 3D Printer\" href=https://www.matterhackers.com/"https://www.matterhackers.com/store/l/modix-big-60-v4-3d-printer-kit-1/" target=\"_blank\" rel=\"noopener\">BIG-60</a></th>\r\n<th class=\"align-center\"><a title=\"BIG-120X 3D Printer\" href=https://www.matterhackers.com/"https://www.matterhackers.com/store/l/modix-big-120x-v4-3d-printer-kit/" target=\"_blank\" rel=\"noopener\">BIG-120X</a></th>\r\n<th class=\"align-center\"><a title=\"Modix BIG-120Z 3D Printer\" href=https://www.matterhackers.com/"https://www.matterhackers.com/store/l/modix-big-120z-v4-3d-printer-kit/" target=\"_blank\" rel=\"noopener\">BIG-120Z</a></th>\r\n<th class=\"align-center\"><a title=\"Modix BIG-METER 3D Printer\" href=https://www.matterhackers.com/"https://www.matterhackers.com/store/l/modix-big-meter-v4-3d-printer-kit/" target=\"_blank\" rel=\"noopener\">BIG-METER</a></th>\r\n<th class=\"align-center\"><a title=\"BIG-180X 3D Printer\" href=https://www.matterhackers.com/"https://www.matterhackers.com/store/l/modix-big-180x-v4-3d-printer-kit/" target=\"_blank\" rel=\"noopener\">BIG-180X</a></th>\r\n</tr>\r\n<tr>\r\n<th class=\"align-left\">Print Volume<br />(XYZ)</th>\r\n<th class=\"align-center\">600 × 600 × 660mm<br /><br />~23.6\" × 23.6\" × 26\"</th>\r\n<th class=\"align-center\">1200 × 600 × 640mm<br /><br /> ~47.2\" × 23.6\" × 25.2\"</th>\r\n<th class=\"align-center\">600 × 600 × 1200mm<br /><br />~23.6\" × 23.6\" × 47.2\"</th>\r\n<th class=\"align-center\">1010 × 1010 × 1010mm<br /><br /> ~39.7\" × 39.7\" × 39.7\"</th>\r\n<th class=\"align-center\">1800 × 600 × 600mm<br /><br />~70.8\" × 23.6\"× 23.6\"</th>\r\n</tr>\r\n<tr>\r\n<td><strong>Machine Size<br />(WxDxH)</strong></td>\r\n<td class=\"align-center\">906 × 1060 × 1356mm<br /><br />~35.6\" × 41.7\" × 53.4\"</td>\r\n<td class=\"align-center\">1556 × 1060 × 1506mm<br /><br />~61.2\" × 41.7\" × 59.2\"</td>\r\n<td class=\"align-center\">906 × 1060 × 1916mm<br /><br />~35.6\" × 41.7\" × 75.4\"</td>\r\n<td class=\"align-center\">1739 × 1424 × 1808mm<br /><br />~68.4\" × 56\" × 71.1\"</td>\r\n<td class=\"align-center\">2630 × 1060 × 1573mm<br /><br />~85.4\" × 41.7\" × 62\"</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Shipping Weight</strong></td>\r\n<td class=\"align-center\">120 KG<br />~265 lbs</td>\r\n<td class=\"align-center\">170 KG<br />~325 Ibs</td>\r\n<td class=\"align-center\">140 KG<br /> ~265 Ibs</td>\r\n<td class=\"align-center\">200 KG<br /> ~440 Ibs</td>\r\n<td class=\"align-center\">210 KG<br /> ~465 Ibs</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Enclosure</strong></td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n</tr>\r\n<tr>\r\n<td><strong>IDEX</strong></td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Z Axis Guides</strong></td>\r\n<td class=\"align-center\">Hiwin Rails<br /><strong>Optional</strong></td>\r\n<td class=\"align-left\">\r\n<p class=\"align-center\">Hiwin Rails<br /><strong>Optional</strong></p>\r\n</td>\r\n<td class=\"align-center\">Hiwin Rails<br /><em>Included</em></td>\r\n<td class=\"align-center\">Hiwin Rails<br /><em>Included</em></td>\r\n<td class=\"align-center\">Hiwin Rails<br /><em>Included</em></td>\r\n</tr>\r\n<tr>\r\n<td><strong>DUEX<br />Expansion board</strong></td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Tilt screen &<br />emergency button</strong></td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Optional</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Casters</strong></td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Optional</td>\r\n<td class=\"align-center\">Included</td>\r\n<td class=\"align-center\">Included</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Base Price</strong></td>\r\n<td class=\"align-center\">4,900 USD</td>\r\n<td class=\"align-center\">7,500 USD</td>\r\n<td class=\"align-center\">7,500 USD</td>\r\n<td class=\"align-center\">13,500 USD</td>\r\n<td class=\"align-center\">15,500 USD</td>\r\n</tr>\r\n<tr>\r\n<td><strong>Packing lists</strong></td>\r\n<td class=\"align-center\"><a href=https://www.matterhackers.com/"http://www.support.modix3d.com/wp-content/uploads/2022/12/MODIX-V4-BOM-BIG60-_BATCH_33.pdf/">Big-60/r/n

Big-120X | /r/n

Big-120Z | /r/n

Big-Meter | /r/n

Big-180X | /r/n/r/n/r/n

/r/n

here. /r/n

How long will it take to my purchase from MatterHackers to be shipped?</strong></p>\r\n<p>Items purchased from MatterHackers will be shipped from the manufacturer's US-based warehouse. There may be a lead time on orders, depending on stock availability</p>\r\n<p><strong>Can I return a 3D printer kit if it has been opened?</strong></p>\r\n<p>Returns will not be accepted for any opened 3D printer kit. New, unopened 3D printer kits may be returned within 30 days of purchase.</p>\r\n<p><strong>What kind of support does MatterHackers provide for warranty replacement components?</strong></p>\r\n<p>MatterHackers provides support for warranty replacement components. Assembly instruction, troubleshooting, and technical support are provided directly by the Modix Support team.</p>", "Images": [], "Type": "Text", "ElementCode": "8J29O8"}], "HasBeenPublished": true, "DisableAddToCart": true, "HideRewardsFlag": false, "TemplateKey": "", "IsCustomizable": false, "ShowAddToCart": false, "Key": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCww", "PreOrderFlag": false, "FeaturedImage": {"ImageFile": "/mh-product-images/prod/91f1d09b-50eb-4d26-9977-e3ee6ac1cca7", "IsFeatured": true, "ImageUrl": "https://lh3.googleusercontent.com/66OTH_EU6RfzNV0EBn4nKtP1uEwfI8fOiVerGfWmQE451-JKqx5VmnwgrTdm0IzWk9V9KhnkaabtphqOCK2pkHWYkjKLIwJ0g8lN"}, "IsCustomizablePart": false, "DateTimeCreated": "2023-10-26T23:42:46.314784", "IsDeprecated": false, "IsConfigurableMultiSku": true, "Images": [{"ImageFile": "/mh-product-images/prod/91f1d09b-50eb-4d26-9977-e3ee6ac1cca7", "IsFeatured": true, "ImageUrl": "https://lh3.googleusercontent.com/66OTH_EU6RfzNV0EBn4nKtP1uEwfI8fOiVerGfWmQE451-JKqx5VmnwgrTdm0IzWk9V9KhnkaabtphqOCK2pkHWYkjKLIwJ0g8lN"}, {"ImageFile": "/mh-product-images/prod/7c86a22c-4b56-4e54-ad2c-d445ef2beece", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/MwNZOqTc-58_V4bOZm0y8kSOcs_lBwpfBzuhBoHZwO4AQ3wuhPNYu8EJezqL-ZO2VkYv5ZQNWQijArq54kjFXn6OcKZ9rCXfDGch"}, {"ImageFile": "/mh-product-images/prod/1b3b10bf-7389-4dd8-a0ad-c0fb2c78ba45", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/S5plqXbSg1tcI4jZd-1RpqIOKMsNWv6kA-3LWmyAS8wT5YAFIGa_SsE-4qnp-GqlniGzioWJgTqxBW8RuMRshUOSYA89OcgXKj6N"}, {"ImageFile": "/mh-product-images/prod/ecea34ef-8f96-4d27-ae55-50052c741aeb", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/9lGySZMnWcUrhg-Q37GI7Wnt2QISTgIfKvTCYmRHA3fkXvTaM7lGQvD6pP0zqqiTss-XjXa11ZO2yRYPp_tVtMsrynSv8xD8jZUd"}, {"ImageFile": "/mh-product-images/prod/a3f10edc-a805-4459-830e-4e1c27f4c76a", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/BUNF37Lhtku2QTvtGB7I38wIb33ZYwc8bQlxDrZMRv8Uniw0yp7VZesjb4LpSsdw6_MMTf4H8WMYVTLTdJ8_T4Qa0whlPtcPS7M"}, {"ImageFile": "/mh-product-images/prod/655f4d14-f5fe-4282-9e81-35f605dbd373", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/IYMmNXRlubBq4jyzYzQxx_G4-Qd9WZb6I1lgKWZlq-xhWANZqRsGXjqApnyUDwhN2JS89LwEl8wwzxfJZwuHH5hzH-qnF44MJcYF"}, {"ImageFile": "/mh-product-images/prod/ec6c9b43-6ecb-40a9-b148-80df8bd61ad3", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/gC8ynQQ7jyCT_UmT5FISkV9Ib1WDhYYKdd_L3qytBvMwV9N3hxIaJKaPDqSpqKv6oOxdURS3oO18RAnuSwqcJg8zIq9pPyEJBRYl"}], "HideSuccessGuaranteeFlag": false, "IsSearchable": true, "Attributes": ["ag1zfm1oLXBscy1wcm9kcjgLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4OjXkJQJDA", "ag1zfm1oLXBscy1wcm9kcjgLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4Ij-7aUIDA", "ag1zfm1oLXBscy1wcm9kcjgLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4PC_gusLDA", "ag1zfm1oLXBscy1wcm9kcjgLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4KjhuJ0JDA", "ag1zfm1oLXBscy1wcm9kcjgLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4MiImskLDA"], "ActiveSIDs": ["MPHAV1KV", "M7ZG1NHK", "ME7Z5YM1", "MV4GDKAC", "M29E6Y8J", "MGMY0M0F", "M1NYEF81", "MHRC440J", "M1EY9HVP", "MDZLU4J7", "MZ2MMND2", "MQWFZ6HM", "MZXAYWUN", "MEGE2NXV", "M2HSRWTH", "MP673E2W", "MZ1KJSCV", "MQR5F8SU", "MAV27RXK", "M7M78WGG", "MJC38TEJ", "MJSTW9PX", "MHYXHCXE", "MAMF9R8G", "MY4KN6GL", "MRP17DJA", "MKRYAYP3", "MZV413JL", "M0F4U6UC", "MJVJDV4R", "M4ZZZ3C2", "M373GA9P"], "ID": 6411140516544512, "MaxPriceRange": 2033000, "Subtitle": "", "ProductCollectionKey": "ag9zfm1hdHRlcmhhY2tlcnNySgsSEVByb2R1Y3RDb2xsZWN0aW9uIjNQcm9kdWN0Q29sbGVjdGlvbjpfbGlzdGluZy13aWRnZXQtbW9kaXgtM2QtcHJpbnRlcnMM", "ShortDescription": "The Modix BIG-180X V4 is a large-scale 3D printer designed for professionals and innovators. It has a massive print volume of 1800\u00d7600\u00d7600mm and comes as a self-assembly kit. Known for its high-quality components, durability, and great price-performance ratio, it also offers upgrade options for customization. The printer uses top components from brands like E3D, Duet, and Hiwin, ensuring reliability and capacity for future upgrades.\r\n\r\n- Massive print volume of 1800\u00d7600\u00d7600mm\r\n- High-quality components\r\n- Heavy-duty design for robust output\r\n- Assembly & Installation Services Available\r\n", "MinPriceRange": 1550000, "ActiveSkus": ["ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUEhBVjFLVgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNN1pHMU5ISww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNRTdaNVlNMQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNVjRHREtBQww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMjlFNlk4Sgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNR01ZME0wRgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMU5ZRUY4MQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSFJDNDQwSgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMUVZOUhWUAw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNRFpMVTRKNww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWjJNTU5EMgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUVdGWjZITQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWlhBWVdVTgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNRUdFMk5YVgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMkhTUldUSAw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUDY3M0UyVww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWjFLSlNDVgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUVI1RjhTVQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNQVYyN1JYSww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNN003OFdHRww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSkMzOFRFSgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSlNUVzlQWAw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSFlYSENYRQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNQU1GOVI4Rww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWTRLTjZHTAw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUlAxN0RKQQw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNS1JZQVlQMww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWlY0MTNKTAw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMEY0VTZVQww", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSlZKRFY0Ugw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNNFpaWjNDMgw", "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMzczR0E5UAw"], "AlwaysInStockFlag": false, "IsAdminSearchable": true, "AddOns": [{"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSzJZRzBTTgw", "AddOnBasePrice": 2000000, "AddOnPreOrderFlag": false, "DisplaySID": "M-K2Y-G0SN", "ProductType": "service", "QuantityAvailable": 33303, "AddOnPrice": 2000000, "AddOnTitle": "Modix Assembly for BIG-180x and BIG-Meter", "AddOnFloatPrice": 20000.0, "ProductAddOnPrice": 2000000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "20,000.00", "AddOnDisplayBasePrice": "20,000.00", "AddOnSavings": 0, "AddOnSkuReference": "MK2YG0SN", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "", "SingleSku": true, "ProductListingKey": null, "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMEE2RlRNUAw", "AddOnBasePrice": 100000, "AddOnPreOrderFlag": false, "DisplaySID": "M-0A6-FTMP", "ProductType": "dropship-freight", "QuantityAvailable": 33303, "AddOnPrice": 100000, "AddOnTitle": "Modix Griffin Ultra Print Head", "AddOnFloatPrice": 1000.0, "ProductAddOnPrice": 100000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "1,000.00", "AddOnDisplayBasePrice": "1,000.00", "AddOnSavings": 0, "AddOnSkuReference": "M0A6FTMP", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-griffin-ultra-print-head", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgOCe_oOCCQw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNS0VFWlJOTAw", "AddOnBasePrice": 20000, "AddOnPreOrderFlag": false, "DisplaySID": "M-KEE-ZRNL", "ProductType": "dropship-freight", "QuantityAvailable": 33303, "AddOnPrice": 20000, "AddOnTitle": "Modix IDEX Calibration Tool", "AddOnFloatPrice": 200.0, "ProductAddOnPrice": 20000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "200.00", "AddOnDisplayBasePrice": "200.00", "AddOnSavings": 0, "AddOnSkuReference": "MKEEZRNL", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-idex-calibration-tool", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgOC-qqnbCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNN1lOVTRZQww", "AddOnBasePrice": 30000, "AddOnPreOrderFlag": false, "DisplaySID": "M-7YN-U4YC", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 30000, "AddOnTitle": "Modix Griffin High-Flow Hotend", "AddOnFloatPrice": 300.0, "ProductAddOnPrice": 30000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "300.00", "AddOnDisplayBasePrice": "300.00", "AddOnSavings": 0, "AddOnSkuReference": "M7YNU4YC", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-griffin-high-flow-hotend", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODCk_vICAw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNOVhNMlEyUgw", "AddOnBasePrice": 11000, "AddOnPreOrderFlag": false, "DisplaySID": "M-9XM-2Q2R", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 11000, "AddOnTitle": "Modix Griffin High-Resolution Hotend", "AddOnFloatPrice": 110.0, "ProductAddOnPrice": 11000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "110.00", "AddOnDisplayBasePrice": "110.00", "AddOnSavings": 0, "AddOnSkuReference": "M9XM2Q2R", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-griffin-high-resolution-hotend", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgOCAlJ-1CAw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUDk2RjYwTAw", "AddOnBasePrice": 16000, "AddOnPreOrderFlag": false, "DisplaySID": "M-P96-F60L", "ProductType": "dropship-freight", "QuantityAvailable": 33303, "AddOnPrice": 16000, "AddOnTitle": "Modix Griffin Spare Hotend", "AddOnFloatPrice": 160.0, "ProductAddOnPrice": 16000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "160.00", "AddOnDisplayBasePrice": "160.00", "AddOnSavings": 0, "AddOnSkuReference": "MP96F60L", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-griffin-spare-hotend", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKDGtZKoCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNOFdXNUs1Sgw", "AddOnBasePrice": 30500, "AddOnPreOrderFlag": false, "DisplaySID": "M-8WW-5K5J", "ProductType": "dropship", "QuantityAvailable": 0, "AddOnPrice": 30500, "AddOnTitle": "Modix E3D Super Volcano HotEnd", "AddOnFloatPrice": 305.0, "ProductAddOnPrice": 30500, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "305.00", "AddOnDisplayBasePrice": "305.00", "AddOnSavings": 0, "AddOnSkuReference": "M8WW5K5J", "IsRetired": true, "QuantityOnHand": 0, "AddOnListingReference": "modix-e3d-super-volcano-hotend-add-on", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgMDJ8MqYCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNTjNEUlVLRQw", "AddOnBasePrice": 23000, "AddOnPreOrderFlag": false, "DisplaySID": "M-N3D-RUKE", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 23000, "AddOnTitle": "Modix Basic Maintenance Kit", "AddOnFloatPrice": 230.0, "ProductAddOnPrice": 23000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "230.00", "AddOnDisplayBasePrice": "230.00", "AddOnSavings": 0, "AddOnSkuReference": "MN3DRUKE", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-basic-maintenance-kit", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgOCAi5KtCQw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNVzdQNVpBTAw", "AddOnBasePrice": 123000, "AddOnPreOrderFlag": false, "DisplaySID": "M-W7P-5ZAL", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 123000, "AddOnTitle": "Modix Advanced Maintenance Kit", "AddOnFloatPrice": 1230.0, "ProductAddOnPrice": 123000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "1,230.00", "AddOnDisplayBasePrice": "1,230.00", "AddOnSavings": 0, "AddOnSkuReference": "MW7P5ZAL", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-advanced-maintenance-kit", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODAwejXCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNNDVBWk4yVgw", "AddOnBasePrice": 17000, "AddOnPreOrderFlag": false, "DisplaySID": "M-45A-ZN2V", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 11000, "AddOnTitle": "Modix PEI Build Surface 660 x 660 mm", "AddOnFloatPrice": 110.0, "ProductAddOnPrice": 11000, "ListingIsActive": true, "AddOnDiscountDisplay": 35, "AddOnDisplayPrice": "110.00", "AddOnDisplayBasePrice": "170.00", "AddOnSavings": 6000, "AddOnSkuReference": "M45AZN2V", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "duplicate-modix-pei-build-surface-465-x-465-mm-add-on", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKDCwqSDCww", "AddOnDisplaySavings": "60.00"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNVE5EUFdZVww", "AddOnBasePrice": 28000, "AddOnPreOrderFlag": false, "DisplaySID": "M-TND-PWYW", "ProductType": "physical-inventory", "QuantityAvailable": 16651, "AddOnPrice": 22000, "AddOnTitle": "Modix PEI Build Surface 660 x 660 mm Add-on - (2 pack)", "AddOnFloatPrice": 220.0, "ProductAddOnPrice": 22000, "ListingIsActive": true, "AddOnDiscountDisplay": 21, "AddOnDisplayPrice": "220.00", "AddOnDisplayBasePrice": "280.00", "AddOnSavings": 6000, "AddOnSkuReference": "MTNDPWYW", "IsRetired": false, "QuantityOnHand": 16651, "AddOnListingReference": "modix-pei-build-surface-660-x-660-mm-add-on-2-pack", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKC0_JvECww", "AddOnDisplaySavings": "60.00"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNTkFDU0M0VQw", "AddOnBasePrice": 150000, "AddOnPreOrderFlag": false, "DisplaySID": "M-NAC-SC4U", "ProductType": "dropship-freight", "QuantityAvailable": 33303, "AddOnPrice": 150000, "AddOnTitle": "Modix Filament Dryer 110V", "AddOnFloatPrice": 1500.0, "ProductAddOnPrice": 150000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "1,500.00", "AddOnDisplayBasePrice": "1,500.00", "AddOnSavings": 0, "AddOnSkuReference": "MNACSC4U", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-filament-dryer", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODehbueCQw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSzJRRzVMSgw", "AddOnBasePrice": 32000, "AddOnPreOrderFlag": false, "DisplaySID": "M-K2Q-G5LJ", "ProductType": "dropship", "QuantityAvailable": 33303, "AddOnPrice": 25000, "AddOnTitle": "Modix Replacement Air Filters", "AddOnFloatPrice": 250.0, "ProductAddOnPrice": 25000, "ListingIsActive": true, "AddOnDiscountDisplay": 21, "AddOnDisplayPrice": "250.00", "AddOnDisplayBasePrice": "320.00", "AddOnSavings": 7000, "AddOnSkuReference": "MK2QG5LJ", "IsRetired": false, "QuantityOnHand": 33303, "AddOnListingReference": "modix-replacement-air-filters", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgMCZrOSZCww", "AddOnDisplaySavings": "70.00"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNVlZIUVRMQQw", "AddOnBasePrice": 57499, "AddOnPreOrderFlag": false, "DisplaySID": "M-VVH-QTLA", "ProductType": "physical-inventory", "QuantityAvailable": 0, "AddOnPrice": 57499, "AddOnTitle": "Slice Engineering Modix Upgrade Kit - Left Toolhead", "AddOnFloatPrice": 574.99, "ProductAddOnPrice": 57499, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "574.99", "AddOnDisplayBasePrice": "574.99", "AddOnSavings": 0, "AddOnSkuReference": "MVVHQTLA", "IsRetired": true, "QuantityOnHand": 0, "AddOnListingReference": "slice-engineering-modix-upgrade-kit-left-toolhead", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKCq-Z2zCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUjlLNjhKRww", "AddOnBasePrice": 56349, "AddOnPreOrderFlag": false, "DisplaySID": "M-R9K-68JG", "ProductType": "physical-inventory", "QuantityAvailable": 0, "AddOnPrice": 56349, "AddOnTitle": "Slice Engineering Modix Upgrade Kit - Right Toolhead *Open Box/Unused*", "AddOnFloatPrice": 563.49, "ProductAddOnPrice": 56349, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "563.49", "AddOnDisplayBasePrice": "563.49", "AddOnSavings": 0, "AddOnSkuReference": "MR9K68JG", "IsRetired": false, "QuantityOnHand": 0, "AddOnListingReference": "slice-engineering-modix-upgrade-kit-right-toolhead-a-stock", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKDKgrGHCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNOUdURVlSNAw", "AddOnBasePrice": 109999, "AddOnPreOrderFlag": false, "DisplaySID": "M-9GT-EYR4", "ProductType": "physical-inventory", "QuantityAvailable": 0, "AddOnPrice": 109999, "AddOnTitle": "Slice Engineering Modix Upgrade Kit - Dual Toolhead", "AddOnFloatPrice": 1099.99, "ProductAddOnPrice": 109999, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "1,099.99", "AddOnDisplayBasePrice": "1,099.99", "AddOnSavings": 0, "AddOnSkuReference": "M9GTEYR4", "IsRetired": true, "QuantityOnHand": 0, "AddOnListingReference": "slice-engineering-modix-upgrade-kit-dual-toolhead", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKCyg93pCww", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNMjdGMTc4WAw", "AddOnBasePrice": 5499, "AddOnPreOrderFlag": false, "DisplaySID": "M-27F-178X", "ProductType": "physical-inventory", "QuantityAvailable": 37, "AddOnPrice": 5224, "AddOnTitle": "Silver MH Build Series PLA Filament - 1.75mm (3kg)", "AddOnFloatPrice": 52.24, "ProductAddOnPrice": 5224, "ListingIsActive": true, "AddOnDiscountDisplay": 5, "AddOnDisplayPrice": "52.24", "AddOnDisplayBasePrice": "54.99", "AddOnSavings": 275, "AddOnSkuReference": "M27F178X", "IsRetired": false, "QuantityOnHand": 37, "AddOnListingReference": "silver-mh-build-series-pla-filament-175mm-3kg", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgKCClOSPCgw", "AddOnDisplaySavings": "2.75"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUFVQRFBFTgw", "AddOnBasePrice": 33500, "AddOnPreOrderFlag": true, "DisplaySID": "M-PUP-DPEN", "ProductType": "physical-inventory", "QuantityAvailable": 296, "AddOnPrice": 37000, "AddOnTitle": "NylonX Carbon Fiber Filament - 1.75mm (3kg)", "AddOnFloatPrice": 370.0, "ProductAddOnPrice": 37000, "ListingIsActive": true, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "370.00", "AddOnDisplayBasePrice": "335.00", "AddOnSavings": -3500, "AddOnSkuReference": "MPUPDPEN", "IsRetired": false, "QuantityOnHand": 296, "AddOnListingReference": "nylonx-carbon-fiber-filament-175mm-3kg", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgICAgPKICgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNSlQyRkdZUww", "AddOnBasePrice": 3890, "AddOnPreOrderFlag": false, "DisplaySID": "M-JT2-FGYS", "ProductType": "physical-inventory", "QuantityAvailable": 19, "AddOnPrice": 3800, "AddOnTitle": "E3D Volcano High Temperature Nozzle X - 1.75mm x 0.40mm", "AddOnFloatPrice": 38.0, "ProductAddOnPrice": 3800, "ListingIsActive": true, "AddOnDiscountDisplay": 2, "AddOnDisplayPrice": "38.00", "AddOnDisplayBasePrice": "38.90", "AddOnSavings": 90, "AddOnSkuReference": "MJT2FGYS", "IsRetired": false, "QuantityOnHand": 19, "AddOnListingReference": "e3d-volcano-nozzle-x-175-040", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgICA0KWVCgw", "AddOnDisplaySavings": "0.90"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUlZTSFpUTQw", "AddOnBasePrice": 3890, "AddOnPreOrderFlag": false, "DisplaySID": "M-RVS-HZTM", "ProductType": "physical-inventory", "QuantityAvailable": 7, "AddOnPrice": 3800, "AddOnTitle": "E3D Volcano High Temperature Nozzle X - 1.75mm x 0.60mm", "AddOnFloatPrice": 38.0, "ProductAddOnPrice": 3800, "ListingIsActive": true, "AddOnDiscountDisplay": 2, "AddOnDisplayPrice": "38.00", "AddOnDisplayBasePrice": "38.90", "AddOnSavings": 90, "AddOnSkuReference": "MRVSHZTM", "IsRetired": false, "QuantityOnHand": 7, "AddOnListingReference": "e3d-volcano-nozzle-x-175-060", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgIDA3PmTCgw", "AddOnDisplaySavings": "0.90"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNWkZNVkRERww", "AddOnBasePrice": 3890, "AddOnPreOrderFlag": false, "DisplaySID": "M-ZFM-VDDG", "ProductType": "physical-inventory", "QuantityAvailable": 1, "AddOnPrice": 3800, "AddOnTitle": "E3D Volcano High Temperature Nozzle X - 1.75mm x 0.80mm", "AddOnFloatPrice": 38.0, "ProductAddOnPrice": 3800, "ListingIsActive": true, "AddOnDiscountDisplay": 2, "AddOnDisplayPrice": "38.00", "AddOnDisplayBasePrice": "38.90", "AddOnSavings": 90, "AddOnSkuReference": "MZFMVDDG", "IsRetired": false, "QuantityOnHand": 1, "AddOnListingReference": "e3d-volcano-nozzle-x-175-080", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgICA0LOMCgw", "AddOnDisplaySavings": "0.90"}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNREpOSFlYNQw", "AddOnBasePrice": 5000, "AddOnPreOrderFlag": false, "DisplaySID": "M-DJN-HYX5", "ProductType": "physical-inventory", "QuantityAvailable": 3, "AddOnPrice": 5000, "AddOnTitle": "Modix E3D Volcano Brass Nozzle Bundle", "AddOnFloatPrice": 50.0, "ProductAddOnPrice": 5000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "50.00", "AddOnDisplayBasePrice": "50.00", "AddOnSavings": 0, "AddOnSkuReference": "MDJNHYX5", "IsRetired": false, "QuantityOnHand": 3, "AddOnListingReference": "modix-e3d-volcano-brass-nozzle-bundle", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODUk-TbCgw", "AddOnDisplaySavings": null}, {"ProductSkuKey": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNQ1hUWVY4UAw", "AddOnBasePrice": 15000, "AddOnPreOrderFlag": false, "DisplaySID": "M-CXT-YV8P", "ProductType": "physical-inventory", "QuantityAvailable": 19, "AddOnPrice": 15000, "AddOnTitle": "Modix E3D Volcano High Temp Nozzle Bundle", "AddOnFloatPrice": 150.0, "ProductAddOnPrice": 15000, "ListingIsActive": false, "AddOnDiscountDisplay": null, "AddOnDisplayPrice": "150.00", "AddOnDisplayBasePrice": "150.00", "AddOnSavings": 0, "AddOnSkuReference": "MCXTYV8P", "IsRetired": false, "QuantityOnHand": 19, "AddOnListingReference": "modix-e3d-volcano-high-temp-nozzle-bundle", "SingleSku": true, "AlwaysInStockFlag": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgOD06LzFCAw", "AddOnDisplaySavings": null}], "ProductCreatedOn": "2023-10-26T23:42:46.314776", "IsActive": true}, "ProductNumber": null, "AverageInboundFreight": 0, "DisplayListPrice": "15,500.00", "ReferenceUrl": "modix-big-180x-v4-3d-printer-kit", "AttributeOptionKeys": ["ag1zfm1oLXBscy1wcm9kclsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4OjXkJQJDAsSFlByb2R1Y3RBdHRyaWJ1dGVPcHRpb24YgIDgqKHzlQkM", "ag1zfm1oLXBscy1wcm9kclsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4Ij-7aUIDAsSFlByb2R1Y3RBdHRyaWJ1dGVPcHRpb24YgIDgqKHvjAkM", "ag1zfm1oLXBscy1wcm9kclsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4PC_gusLDAsSFlByb2R1Y3RBdHRyaWJ1dGVPcHRpb24YgIDg6I3QnAkM", "ag1zfm1oLXBscy1wcm9kclsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4KjhuJ0JDAsSFlByb2R1Y3RBdHRyaWJ1dGVPcHRpb24YgIDg6Nf0jQkM", "ag1zfm1oLXBscy1wcm9kclsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCwwLEhBQcm9kdWN0QXR0cmlidXRlGICA4MiImskLDAsSFlByb2R1Y3RBdHRyaWJ1dGVPcHRpb24YgIDgqL_jwQoM"], "ProductType": "dropship-freight", "DisplayPrice": "15,500.00", "ContributionProfitAdjustmentNote": "", "AverageShippingCost": 20, "TotalWeight": 0, "ProductPriceSync": true, "DisableAddToCart": true, "PromotionDescription": "PROMO - Get a FREE Modix Griffin Ultra Print Head with the purchase of any Modix 3D Printer Kit - Offer ends 6/1/2024", "ProductUrl": "https://www.matterhackers.com/store/l/modix-big-180x-v4-3d-printer-kit", "SkuWarningMessages": [], "DisplayAverageShippingCost": "0.20", "Key": "ag1zfm1oLXBscy1wcm9kchgLEgpQcm9kdWN0U2t1IghNUEhBVjFLVgw", "ShipInBox": false, "WholesaleCost": 1240000, "DigitalLicenseKeys": [], "FeaturedImage": {"ImageFile": "/mh-product-images/prod/128ee7b9-da1f-42b5-919f-62da7d74bc0d", "IsFeatured": false, "ImageUrl": "https://lh3.googleusercontent.com/9-_eBO-fFczwStWbNf-2abSYkm3sc5s_bl9kZ_00PJ-aNWaQkofHWHo6qapDz9j4LJ-mlQTUiBNeP21Z81F0_lshWAxApaXSsH6K"}, "DisplayComponentShippingPrice": "0.00", "AverageInboundTariff": 0, "ProductDescription": "The Modix BIG-180X V4 is a large-scale 3D printer designed for professionals and innovators. It has a massive print volume of 1800\u00d7600\u00d7600mm and comes as a self-assembly kit. Known for its high-quality components, durability, and great price-performance ratio, it also offers upgrade options for customization. The printer uses top components from brands like E3D, Duet, and Hiwin, ensuring reliability and capacity for future upgrades.\r\n\r\n- Massive print volume of 1800\u00d7600\u00d7600mm\r\n- High-quality components\r\n- Heavy-duty design for robust output\r\n- Assembly & Installation Services Available\r\n", "DateTimeCreated": "2020-10-12T21:56:03.823287", "ShowAvailableDate": false, "BarCodeID": "", "AlwaysInStockFlag": false, "QuantityReserved": 0, "RequireFulfillmentVerification": false, "ProductListingKey": "ag1zfm1oLXBscy1wcm9kchsLEg5Qcm9kdWN0TGlzdGluZxiAgODI39yxCww", "DisplayContributionProfitAdjustment": "0.00", "QuantityOnHand": 33303, "DisplayWholesaleCost": "12,400.00", "VendorItemID": "180X-US / 180X-EU", "PackageDimensions": ["0.00", "0.00", "0.00"], "DutiesPercentage": 0.0, "LegacyPartNumber": "", "Weight": 0, "FulfillmentVerificationRequired": true, "TotalProductShippingPrice": 165000, "IsOneTimeItem": false, "WeightPounds": "0.00", "SuccessRatingScore": 10000, "IsOnClearance": false, "CreatedBy": "", "DisplayShippingPrice": "1,650.00", "NoPOBox": false, "IsRefurbished": false, "DisplayCalculatedWholesaleCost": "12,400.00", "ShownInListing": true, "Brand": "Modix3D", "WeightGrams": "0.00"}"/>